Rectangular Premier Chuck

Premier range grinding chucks provide precision performance

Hello...

Would you like to visit the Eclipse Magnetics US site to view all relevant content for your location?

If used correctly our magnetic chucks can be used to drive time, quality and money saving efficiencies into your business. Below are some useful workholding tips that can help you 'Work Smart with Magnetic Chucks'.

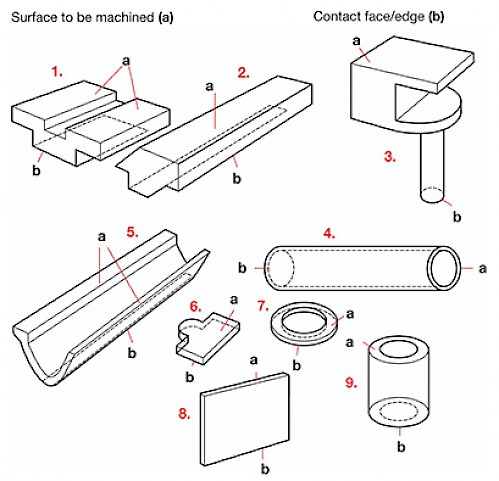

Most workpieces which are difficult to hold have the common problem of small surface area in contact with the chuck top plate. Each of the workpieces below can be held magnetically using the techniques as shown beside image. Simple jigs made from mild steel and non-magnetic material make the holding of such workpieces easy and give positive location time after time.

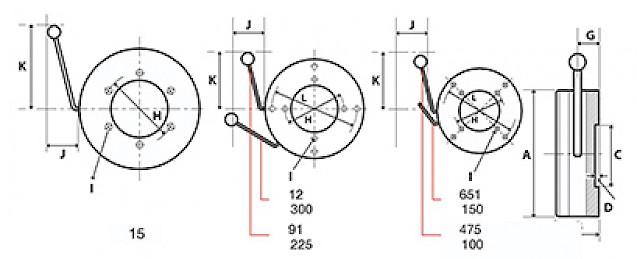

For toolroom and ‘one-off’ applications the simplest of these jigs are Eclipse Chuck blocks, of laminated mild steel and resin construction. They can be machined with Vee’s etc. if necessary. Chuck blocks extend the lines of magnetism from the chuck’s North and South poles. Correct positioning on the chuck is therefore important to obtain the best workholding.

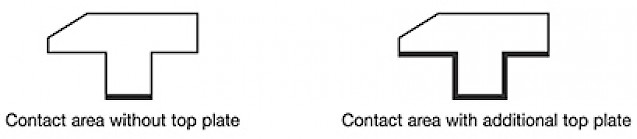

For repetitive or production work an additional top plate can be purchased and profiled to suit the workpiece. In this case the surface area is increased considerably and the pull is increased by 250%.

For deeper workpieces a simple jig is made from mild steel and a non-magnetic material. This makes their holding and positioning simple giving accurate location time after time. For small components the effective contact area can be increased by multiple loading and packing around the sides and ends to give additional support. For one off machining of small, thin components a Fine Pole Chuck should be used. The component being placed across a brass lamination to achieve maximum hold.

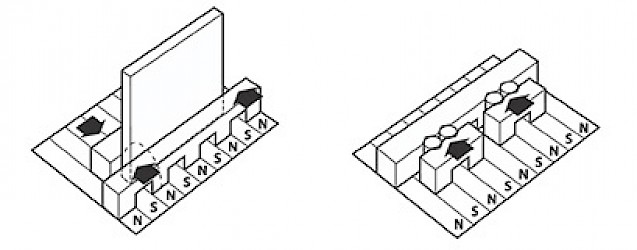

For flat of tall thin parts a magnetic vice effect can be easily achieved with one jaw sitting only on the North poles and the other on the South. When a ferrous workpiece is positioned between the jaws the flux has a complete circuit back to the chuck and the workpiece is held without distortion, between the jaws. Alternatively an Eclipse Magnetic Vice (E927) can be used in conjunction with any chuck or on its own.

Such units can be designed and supplied to suit your workpiece. Please contact our Sales Office for details.

The use of magnetic workholding in milling or machining centre operations can give considerable savings in:

It is recommended that the machining rates for each job are assessed and gradually built up to the optimum until sufficient data is achieved about materials, contact areas, workpiece thickness etc. To ensure maximum rigidity of the workpiece it is recommended that extra packaging/location pieces are used, when the full chuck area is not being utilised.

The mechanical forces to be resisted in milling are generally very much greater than in grinding, and the cutting action may be of an intermittent nature as each cutting edge strikes the workpieces. Furthermore, the direction of the forces varies from instant-to-instant during machine operations.

The purpose of a chuck is to hold work down. Resistance to sideways movement is approximately five times less than the downward pull and it is therefore important to use the side and end stops. Suitable blocks positioned between the side and end stops and the workpiece should be used to ensure the workpiece is over North and South pole.

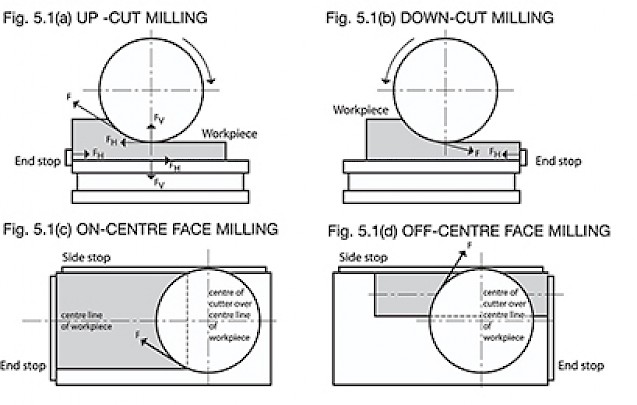

Climb milling is advised in preference to orthodox milling. During vertical milling, the position of the table should be adjusted to control the directions of the mechanical forces so that the workpiece is pressed against the stops and not driven away from them. The centre of the milling cutter should move along the centre line of the workpiece whenever possible.

It is therefore worthwhile to make a quick check before the feed is engaged to ensure that the workpiece, end-stop, side-stop, packings and thrust blocks are in the correct position to suit the particular cutting conditions. For heavy milling and awkward shapes, Eclipse recommend the use of their ‘Power Matrix’ Square Pole Chucks.

All Eclipse chucks have their top plates and base plates accurately ground flat and parallel before despatch, and are ready for immediate use.

However, careful checking is recommended before the chucks are installed on machines as there is always the possibility of damage in transit, unpacking or subsequent handling.

Installing chucks on machines: the vitally important requirements for high-precision machining apply to the installation of magnetic chucks of all types and not only those for high-precision work. The normal installation procedure is as follows:

The most important rule is the machining, whether drilling or otherwise, must NOT penetrate to the interior of any chuck. Drilling must not be so deep as to cause a projection inside a chuck. Penetration to the interior of a chuck could cause a loss of lubricant and admit coolant and dirt. Projections could interfere with the moving magnet system. Holes drilled should be at least 5mm (13/64") less in depth than the thickness of the top plate or base plate. Holes should not be drilled in mild steel inserts or non-magnetic spacers, but in solid parts of the top plates.

Fine Pole chucks have a laminated top plate secured by tie-rods. These top plates can be drilled in any location OTHER than through these tie-rods. Tie-rod locations are easily visible from the chuck ends. Again, drilled holes should be at least 5mm less in depth than the thickness of the top plate.

Within these limitations there is considerable freedom for simple machining in the top plate and base plate of any Eclipse chuck. For example, locating pegs and driving pegs can easily be fitted.

More complex machining may be contemplated to accommodate workpieces that cannot be held directly on the normal chuck surface. It is wise to give careful consideration of additional top plates and other magnetic fixtures to hold awkward shaped workpieces, before deciding on any but the simplest machining.

The machining of grooves, slots or recesses in top plates might be practicable and permissible, and ideal for the operation immediately ahead, but can spoil the chuck for other workpieces in the future. When an additional top plate is used, the basic chuck is unspoilt.

If machining other than the simplest kind seems unavoidable, the problem should be referred to our Technical Department. If machining of the chuck is then considered to be the best course, a check will be made for possible interference with assembly screws and dowel pins, and for any other possible adverse effects, and the customer advised accordingly.

The information below gives a simple cross-check to possible problems, if difficulties are still experienced please contact our technical department.

Problem Possible Cause

Action