Deep Hole Drilling

Company Name: Mollart Engineering Ltd

Location: Chessington, Surrey

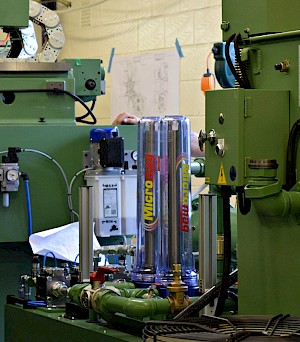

Eclipse Product Installed: MicroMag MM20

Industry: Pellet Die Industry

Process Type: Deep hole drilling

Our Client

Mollart Engineering is a precision mechanical engineering business specialising in the design and manufacture of deep hole drilling machine tools, tooling, gundrills, deep hole boring and bore finishing. With headquarters, design and manufacturing operations in Chessington, Surrey, and a modern production facility in Resolven, South Wales, Mollart also has a high level of expertise as subcontract machinist and fabricator based on adding value to deep hole processing and general machining.

Mollart is also a world leader in multi-spindle gundrilling centres for the pellet die industry. These gundrilling centres can be used to make dies to create pellets from a variety of materials including wood, coal, and animal feed. One of the biggest usages is for the creation of biomass pellets for biomass boilers. As an industry that is still growing, the demand for biomass fuel continues to increase. Biomass pellets are created by pushing wood pulp through a die, which is crushed by heavy rollers to produce pellets.

The holes that are formed in the die are drilled using the gundrilling centre, producing a precise and accurate hole suitable for the creation of the biomass pellets.Depending on what the die is going to be used for, up to 200,000 holes may be required on a single die and some produce several hundreds of tonnes of pellets an hour. Due to this high level of use, the dies inevitably wear out and need to be replaced, and are, therefore, consumables. It is imperative that the holes in the dies are drilled effectively and accurately with a good surface finish. This is dependent on the maintenance of the plant to a high standard, including ensuring that the drill is kept in good shape and the oil remaining clean.

The Challenge

One of the main materials used to make the dies is a chrome alloy steel called XC40. XC40 naturally produces a large amount of very fine swarf particulate (almost like dust) when drilled at the feed rate the Mollart machine is capable of, which is 400 – 500mm per minute. This fine, dust-like particulate inevitably ends up contaminating the oil, resulting in the circulation of particles. When the particles settle in the tank a thick paste-like substance is formed. If this residue is left in the bottom of the tank of the machine, it is at risk of being picked up by the pump, which would have catastrophic effects on the pump itself and render it useless.

Pumps cost approximately £3000 each as a minimum, and can cost up to £5000 for larger pumps, therefore protecting them is a must. Customers who used paper filters as a primary method of filtration alone were experiencing problems with the build-up of particulate and debris in the machine, which put their pumps at risk. In some instances, pump failure would occur due to contamination. A secondary filter, therefore, was required to remove sub-micron particulate from the oil and keep it as clean as possible.

The Solution

A solution was found in the MicroMag magnetic filter from Eclipse Magnetics, which Mollart now installs on the vast majority of the pellet die machines that they design, manufacture and supply. On occasions where Mollart fit only one MicroMag, it is used to polish the oil after it has gone through another form of media, usually paper, first. The oil is passed through the MicroMag, and then through the heat exchanger in order to reduce the temperature. This is a continuous process; for machines that have a 2000 - 3000 litre tank, for instance, Mollart may only be using 100 - 250 litres per minute of oil. The Micromag itself is not directly in the high pressure oil line, therefore it is allowed to work at its own pace, and even if the machine isn’t working the polishing of the oil is still being carried out.

The XC40 chrome alloy steel is a martensitic material but contains chrome, which is non-magnetic. However, the ferrite particulate that is collected gathers to form a ‘beard’ on the magnets within the filter, which helps them to catch even the non-magnetic particles, and therefore work efficiently.

In some systems, a series of 6 MicroMag MM20s are used as a pre-filter, which vastly reduce the cost and usage of the paper media. The flow rate of the systems is up to 300 litres per minute, and as the MicroMags have a flow rate of up to 150 litres per minute, they have 3 in action and 3 on standby. There is a changeover mechanism incorporated in the form of a 3 way valve so that the MicroMags used can be changed over live without stopping the equipment, enabling continuous 24/7 production.

Comments

Ian Petitt, Sales Director for Deep Hole Drilling Systems at Mollart Engineering Ltd said: “We have been very successful with the MicroMag in this application. The MicroMag has resolved a lot of problems; it’s been a very good, usable tool for us. Not many machines go out without it now.

The good things about Eclipse filters is that you don’t have disposable filtration elements, and that makes a big difference to disposal issues and general running costs. My main aim is to make sure my customers’ pumps not only work effectively, but stay alive for as long as possible. Running costs are always high on the agenda. The pumps are very expensive pieces of equipment, and when they go down it puts a huge amount of stress on the business, as well as costing a fortune to replace. The MicroMag prevents that situation, and by reducing the amount of media used by the customer, their running costs are kept down too.

I recently liaised with a customer in France that was using one of our gundrilling centres. The particular material they were using was creating an awful lot of fine, dust-like particulate during the drilling process. They initially ran the machine using 20 micron filter paper which was doing its job to start with, but 6 months down the line it was being choked by fines. We provided them with a and it immediately and completely eradicated the problem.

Wherever there is a dusty drilling problem with ferritic material, the MicroMag can be very useful!”

Finf out more about Magnetic Filtration or contact us for more details

USA

USA