Machine Efficiencies Achieved in Wire Cutting EDM Application

Location: Manchester, UK

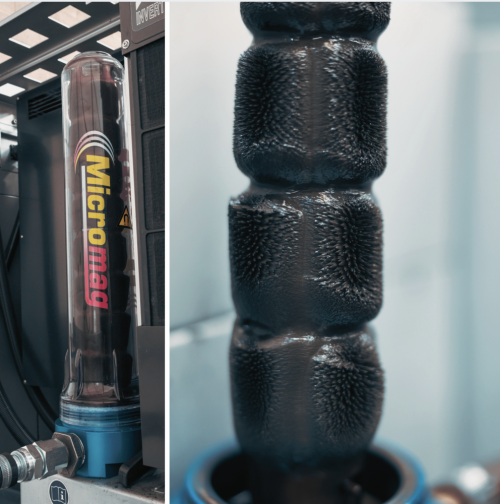

Eclipse Product Installed: MicroMag MM20

Industry: Precision Tools

Process Type: Electrical Discharge Machining (EDM)

Application Background

ADM Precision Tools is a UK manufacturer and supplier of precision tooling components, based in Whitefield, Manchester. Started by Jim Kelly in 1986, an award winning, time served toolmaker with an eye for innovation and a commitment to quality, the company understands the importance of going above and beyond a ‘standard’ service when designing and producing plastic mould tooling.

Operating out of a state-of-the-art, 10,000 square ft. manufacturing facility, ADM Precision Tools produce and test rapid physical prototypes whilst constantly investing in the latest technologies, research, testing and manufacturing methods.

ADM’s expert knowledge allows the business to tackle a wide variety of challenges presented in the plastic mould marketplace. The team carries out complex repair and modification tasks and produce and test rapid physical prototypes meeting tight deadlines.

The Problem

The EDM process is notorious for its inefficiency due to secondary sparking and energy wastage. Wire breakage can also lead to a significant increase in lost production time due to wire re-threading and the problems that can occur from this.

Previously using cartridge filters, whilst still providing effective filtration, were allowing smaller particles that the cartridge filters were not collecting to continue to circulate in the fluids. When particles are present in the dielectric fluid, it can lead to a waste in energy due to secondary sparking as the electrical discharge collides with the particles rather than the work piece. Secondary sparking is common within EDM machining and has been an accepted flaw of the process, however, it can significantly decrease the efficiency of an EDM machine. Due to the fluid being significantly cleaner the process was more robust due to significantly less wire breakages, which in turn made it more efficient.

As part of their efforts to continually improve the effectiveness of their processes, ADM Precision Tools, in conjunction with Eclipse Magnetics and Sodi-tech EDM Ltd., were keen to trial methods to improve the efficiency of its Sodick AQ600L wire erosion machine by improving cycle times and reducing downtime.

The Solution

With the assistance of Sodi-Tech, a global supplier and manufacturer of EDM machines, as part of its R&D programmes in conjunction with Eclipse Magnetics, ADM Precision Tools trialled the MM20 MicroMag magnetic filter from Eclipse’s filtration range to explore the benefits that the filter can bring to EDM machining and the dielectric fluid.

The MicroMag can filter ferrous materials such as Mild Steel, Hardened Steels, Cast Iron, Stainless Steel, Tool Steel, High Speed Steel and Tungsten Carbide etc. from cutting fluid, including dielectric, removing ferrous particles including extremely fine particle matter. Because of fine-particle removal, fluids are much cleaner which, in turn, produces less secondary sparking making the process much more efficient with a significant decrease of energy wastage.

An additional benefit found due to the cleaner fluids was that there were much fewer wire breakages, making the process much more robust. As a result of the decrease in wire breakage, combined with the reduction in secondary sparking, ADM have seen a significant increase in the cutting speed of the machine, with the trial application showing improved results between 17% and 30%.

As an example of the cost savings that the increased machine efficiency can produce, by taking the average between the increased speed results, 23.5%, and converting that into annual hours, that’s a saving of 2,000 hours a year. Using an example hourly cost of £100 an hour, that’s a £200,000-a-year cost saving. This means the MM20 MicroMag unit would offer a return on investment in less than one week.

Due to the magnetic flux circuit geometry of the MM20 MicroMag, it ensures a controlled build-up of contamination meaning the filter can never block. Due to this, there isn’t any significant increase in back pressure, therefore posing no risk to the integrity of the machine and pumps offering complete assurance to those looking to protect their EDM investment.

Comment:

Tom Cooney, Manufacturing Engineer at ADM Precision said: “We fitted the MicroMag MM20 2 months ago and since then have seen a vast improvement in our efficiencies. We have seen an increase in our machine cutting speeds of between 17% and up to 30%, with substantially less wire breakages.”

“It takes a couple of minutes to take the magnet out, clean it into a swarf bin, and then reassemble, so it’s easy and there aren't consumable parts to replace. All-in-all, it proves that the MicroMag units have given us a great improvement, and I’m sure would be a great investment for any EDM machining process.”

Speaking of the trial, Jim Lewis, Sodi-Tech Sales Manager, said: “At Sodi-Tech EDM we sell and support Sodick EDM machines across the UK, to precision operations and whilst our machines are high specification, one of the big questions we are always asked is how can I improve my machine efficiency by improving cycle times and reducing downtime.”

“As part of our R&D programmes in conjunction with Eclipse, ADM trialled the MM20 MicroMag magnetic filter from Eclipse Magnetics. Because the Micromag removes super-fine ferrous particles, it means that fluids are much cleaner and due to the cleaner fluid, you get less secondary sparking making the process much more efficient.”

“In this trial application, we found that cycle times were improved and with less wire breakages you have a more robust process.”

Find out more about Magnetic Filtration in EDM applications or contact us for more details

USA

USA