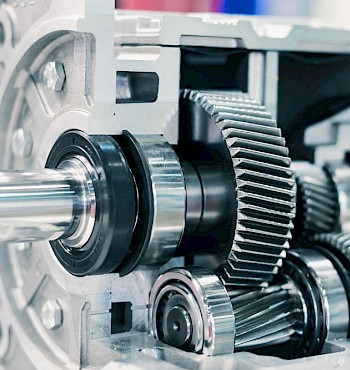

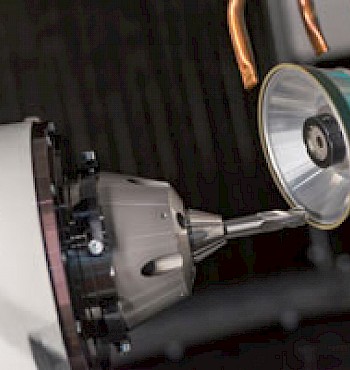

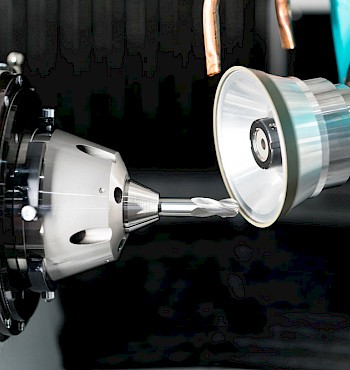

Magnetic filters or magnetic separators are the most effective way of removing problem ferrous particles from industrial fluids such as machine tool coolants, cutting oils, lubricants, grinding fluids and industrial wash solutions.

These filters are widely used in a range of precision machining applications such as precision grinding, honing, lapping, drilling, cutting, steel rolling, EDM, wash stations, and forging.

USA

USA