MicroMag Magnetic Filter

Compact, high-performance magnetic filter (flow rates up to 40 gpm (150 ltrs/min))

Magnetic filtration, also known as magnetic separation, allows for fluid to flow around a magnetic rod or core. This magnet attracts ferrous particles and removes them from the fluid, ensuring that clean fluids are returned to the contact area either on a machine tool or wash system.

When the magnetic core becomes saturated with ferrous contamination, it can then be easily cleaned either manually or automatically.

Our magnetic filters incorporate high-strength neodymium magnets which attract virtually 100% of ferrous particles, including micron size particles. The advanced magnetic core design creates a magnetic field pattern that ensures that the filters do not block, even in high-contamination applications.

Our design and development team has carried out a careful analysis of fluid flow characteristics, ensuring that our range of filters are designed to optimize the fluid flow. As a result, contamination exposure to the magnet is maximized, ensuring almost 100% collection rates WITHOUT interrupting or reducing the fluid rates.

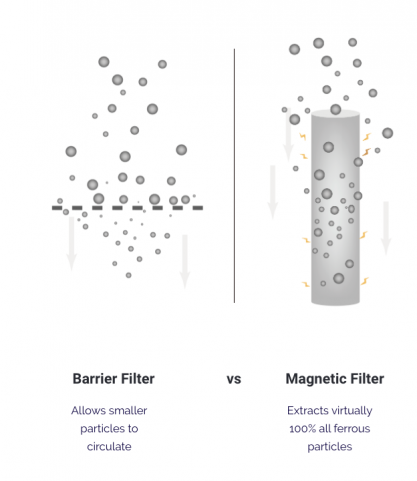

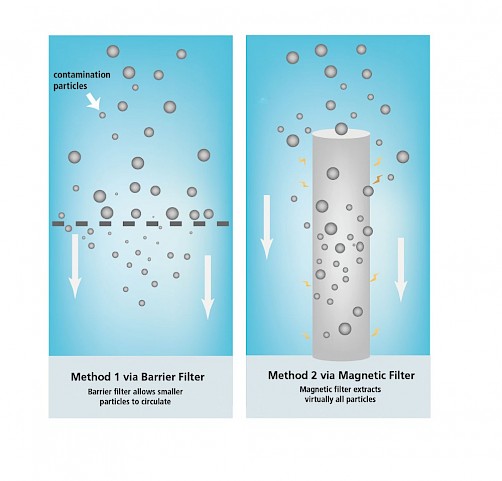

Traditional barrier filters such as paper media and cartridges are constrained by pore size. If the pore is too big then contamination continues to circulate, but if it is too small it blocks. See below:

Barrier Filter

Magnetic Filter

Cleaning magnetic filters is a simple process. With our manual clean filter options, the magnetic cores can be easily removed and scraped clean with a simple cleaning tool. Alternatively, the Automag Skid and Autofiltrex range of magnetic filters provide fully automated options with an integral waste reclaim unit.