Ultralift Plus

A safer way to lift ferrous loads

All lifting systems should be serviced every 12 months by a competant person. As a leading supplier of magnetic lifting equipment, Eclipse Magnetics personnel provide a full inspection and certification service to check any magnetic lifting device (All Manufacturers).

As part of our service, we can carry out any necessary repairs. Using our checking and certification service, you can rest assured your magnetic lifter will remain fit for purpose and certified in accordance with the relevant regulations.

If the magnetic lifter is being used in the EU it must be inspected and maintained in accordance with the requirements of the Provision and Use of Work Equipment Regulations, PUWER (1998) (UK Regulations).

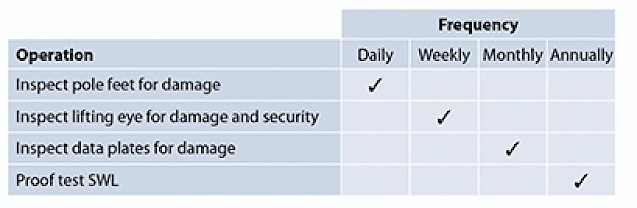

For areas outside the EU the lifter must be inspected and maintained in compliance with local work standards and other standards for suspended load handling. Should the data plates become detached or damaged please contact us immediately for replacements. We recommend the following regular checks to ensure problem-free usage over many years.

All our lifters are covered by a one-year warranty against manufacturing defects. The Ultralift Plus lifting magnet is covered by a 3-year warranty. The warranty is subject to terms and conditions. They must have been used in accordance with the product specifications and guidelines stated in the relevant product manual.

Important Do’s and Don’ts

Always

Never