Efficient milling, grinding or cutting requires good machine selection, quality cutting tools, clean fluids and, equally as importantly, an efficient means of clamping or holding the workpiece. With ever faster processes and cutting speeds, it's a vital consideration.

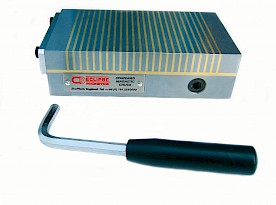

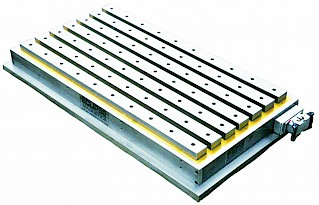

Since inventing the world’s first permanent magnetic chuck in 1934, we have remained at the forefront of workholding systems. We offer a range of permanent magnetic chucks and electro-permanent magnetic chucks for clamping or holding in grinding, milling and cutting applications.

USA

USA