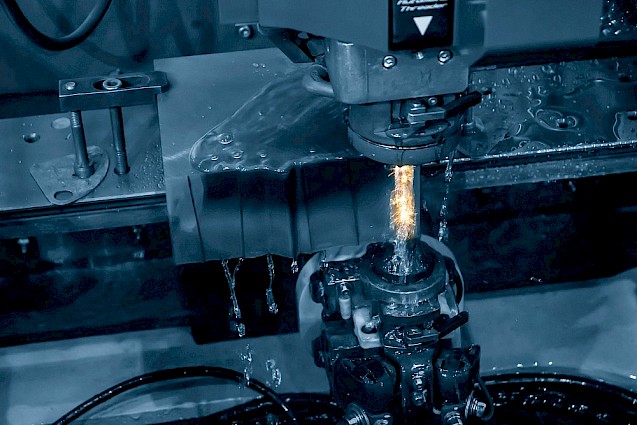

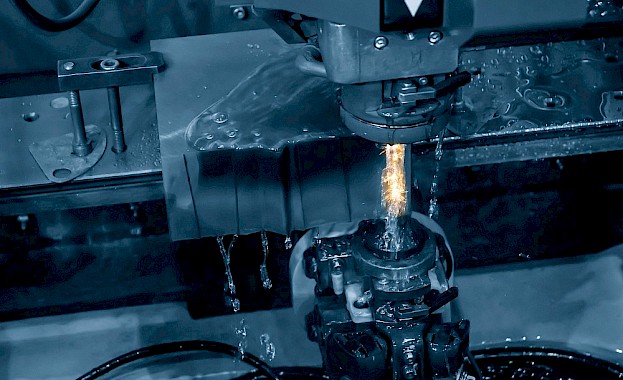

Eclipse Magnetics’ filtration systems are proven to increase wire EDM machine, die-cast machining and EDM drilling efficiency by extending dielectric fluid life, reducing wire consumption and vastly reducing secondary sparking.

Wire Electrical Discharge Machining (EDM), also known as wire-cut EDM, is a very effective way to cut both hard and delicate materials within small tolerances.The high-quality finish and ability to cut intricate and complex shapes has led to the process becoming increasingly popular among manufacturers. However, there are accepted problems with the process that have previously been difficult to overcome. By introducing a cost-effective magnetic filter, manufacturers can reduce these key problems such as secondary sparking or re-sparking, wire breakage and machine downtime to improve the productivity of the machine.

UK

UK