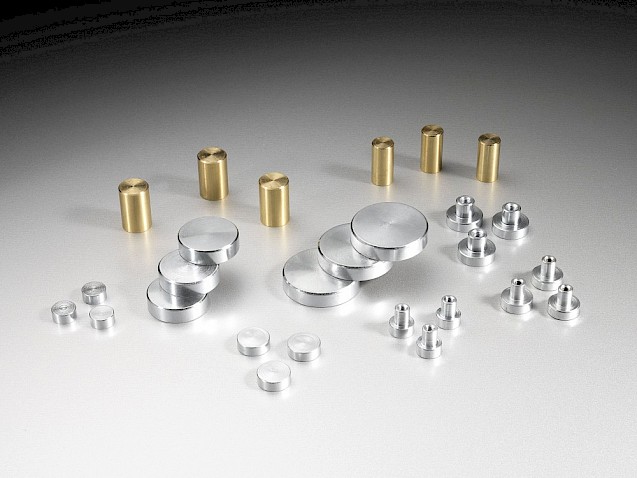

Samarium Cobalt Deep Pot Magnet

Ideal for higher temperature holding and clamping applications

Hello...

Would you like to visit the Eclipse Magnetics US site to view all relevant content for your location?

Samarium Cobalt SmCo is the alternative Rare Earth magnet. It is often used in aerospace, automotive and military applications. It is usually weaker than NdFeB Neodymium at room temperature. Samarium Cobalt SmCo is capable of use in extremes of cold and heat. It also has very high coercivity making it ideal for high temperature motor applications.

Samarium Cobalt also has extremely good temperature coefficients making the magnet output very stable with small changes in temperature. It is very popular in mission-critical sensing applications.

Samarium Cobalt SmCo magnets exist in two alloy varieties. Sm1Co5 (SmCo1:5) is the original SmCo alloy. Sm2Co17 (SmCo2:17) is the more common used and stronger SmCo alloy with SmCo26 being the most popular variety. Sm1Co5 contains mainly Sm and Co and contains no iron (Fe) so it has excellent corrosion resistance. Sm2Co17 is mainly Sm and Co but also contains Cu, Hf &/or Zr, sometimes Pr, and Fe. The low free iron content in Sm2Co17 means it is technically prone to a little surface corrosion when in water. Sm2Co17 is regarded as having good to very good corrosion resistance (far superior to NdFeB) in most applications. A simple coating of NiCuNi will very likely solve any concern of corrosion risk.

Samarium Cobalt magnets (SmCo) may be weaker than NdFeB magnets at room temperature but SmCo will often outperform NdFeB above +150 to +180 deg C (subject to the application and grade). SmCo magnets are ideal for aerospace, automotive, sensor, loudspeaker, motor and military applications. In mission critical applications they are an ideal first choice. SmCo magnets offer minimal change in magnetic output over a small temperature change (with far less variation than NdFeB or ferrite; only Alnico is better). The Low Temperature Coefficient (LTC) versions have less variation in magnetic output with temperature change (due to added Gd and Er). SmCo magnets performance over a massive range of temperatures (from near to −273 deg C up to +350 deg C). The H versions Sm2Co17 have higher Hci and operate up to +350°C rather than +300°C. For note, SmCo30 should perform very similarly to N30 at ambient temperature.

Advantages

Disadvantages

Example

A magnetic pump coupling was required to cope with high temperatures up to and possibly over +300 degrees C (572F). We supplied the H rated SmCo which will cope with temperatures up to +350 degrees C (662F).