Bread Processing

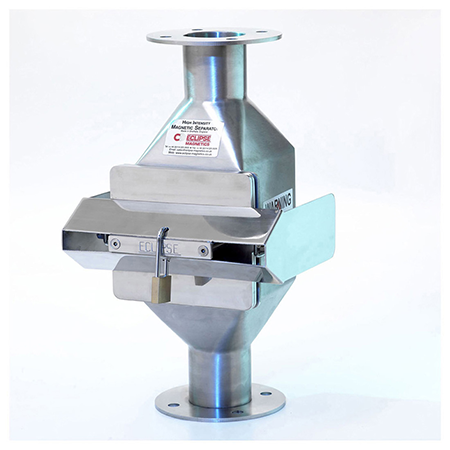

Eclipse Product Installed: Pneumag

Industry: Food

Finished Product: Bread

Application Background

Our separators are widely used in bakeries. This application was for a magnetic separator to be installed at either tanker delivery point and/or before the dough mixing stations.

Problem

Bread manufacturers face a high risk of with metal contamination being present in flour. As a food business they must prove “due diligence” in the control of foreign bodies, one of which is metal.

Solution

In this case Eclipse Pneumag In-line magnetic separators were installed on silo intake and or pre/post sifters, the units are designed to operate in lean phase conveying lines at speeds of up to 20 m/s. The Pneumag is capable of attracting and removing ferrous & paramagnetic contamination from the flour irrespective of the lean phase line being a vacuum or pressure system. Extensive testing and analysis has proven that where ferrous oxide is added to the flour at the mill, a 7,000 Gauss magnet (tested in the outside of the tube) should be used as it allows the permissible amount of ferrous oxide to pass and therefore achieve the correct PPM count.

Find out more about Separation or contact us for more information.

USA

USA