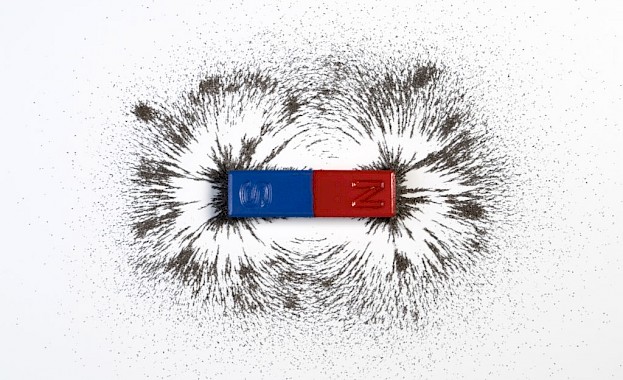

With over 100 years of magnetic expertise, we can help you turn your ideas into profit by maximizing performance efficiency or reducing costs. We work closely with our clients to produce value-added magnetic solutions with either an existing off-the-shelf magnet or designing a bespoke magnet or a full magnetic assembly. With a wealth of magnetic resources and expertise, we can help you fulfill your next-generation design projects.

Off-the-Shelf and Bespoke Magnetic Solutions

Whatever the Project, We Have the Solution

We have access to cutting-edge, high-performance hard, soft and flexible magnet materials, including Neodymium magnets, Samarium Cobalt magnets, Ceramic magnets and Alnico magnets. Each is available in a choice of grades, strengths and surface finishes.

Customized Magnets & Magnetic Assemblies

Using our extensive facilities, we provide customized magnet design, working to precise client specifications. We also design and produce complete customized magnetic assemblies that incorporate the magnet with a non-magnetic alloy or housing. From simple pot magnets to complex motor or audio equipment sub-assembly, we can handle any project. Our focus is giving our customer the edge in the following:-

- Performance advantages e.g. improved accuracy or cycle times

- Design advantages e.g. space-saving designs

- Cost reduction advantages e.g. reduced unit prices

- Reduced lead time or inventory gains

- Environmental advantages e.g. energy saving, waste minimization

Off-the-Shelf Magnets

Often we can provide an immediate off-the-shelf magnet or magnetic assembly available from stock. We have a wealth of stock magnet materials with a wide-ranging choice of shapes, sizes, characteristics and features. We can also provide extensive advice regarding the best magnetic option for your application. Explore our range of stock magnets that can be found in Magnetic Aids & Stock Magnets

Diverse Magnet Applications

Our magnets and magnetic assemblies are widely used in most industries including automotive, food, steel, communications, aerospace and engineering as well as in commercial office and retail premises. We have considerable expertise in producing magnetic assemblies for the electronics, automotive, aerospace, pumps, audio equipment, sensors and security sectors.

Our magnetic expertise is also utilized by research and development companies and academic institutions who are looking for a magnetic assembly or magnetic solution.

If you have a customized magnet or magnetic assembly project to discuss, please contact us.

USA

USA