Neodymium NdFeB Disc Magnets

Ideal where compact size with maximum strength is required

Hello...

Would you like to visit the Eclipse Magnetics US site to view all relevant content for your location?

We are the perfect partner for innovative businesses looking to maximise performance, improve design and reduce costs. We have the expertise to tackle the most challenging of magnetic applications, working with clients to understand their project, then designing, developing and producing a value adding magnetic solution.

As a leading magnet supplier we have the full package of magnet design services in-house gives us full control over costs and planning, thereby ensuring we deliver projects on time and within budget. To find out more click on the sections below or contact us.

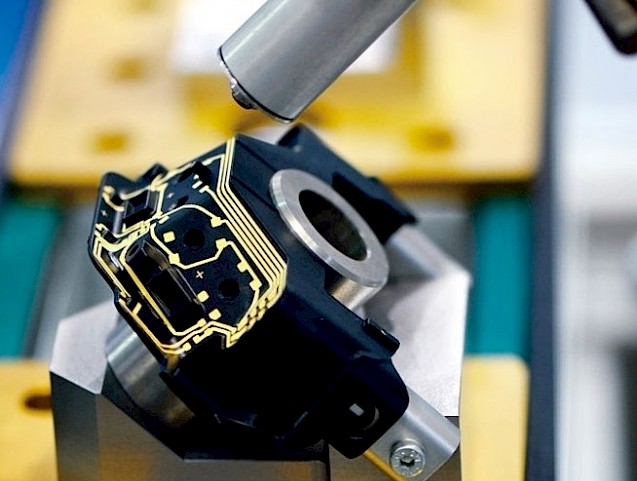

Our magnetic technology, including custom magnet design, can be applied to a vast range diverse applications. Typical examples are listed below:

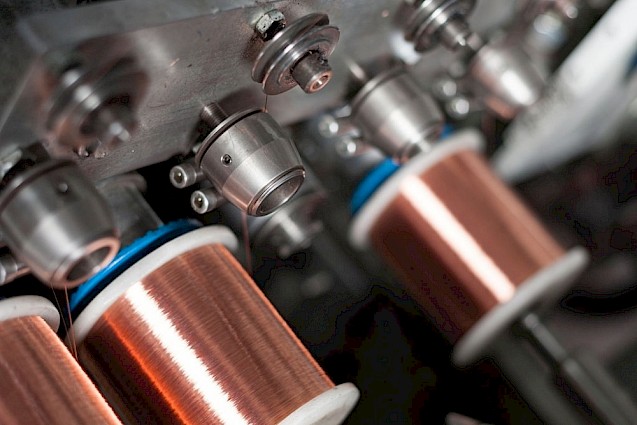

We provide a range of in-house value adding resources and services, allowing us to provide a full custom made magnet service:

As a leading magnet supplier we offer a comprehensive range of material types and can recommend the optimum choice for your application:

We provide a range of specialist finishing operations to give your product the competitive edge: