Energise-to-Hold Electromagnet

When activated provides a clamping, locking or holding mechanism

Hello...

Would you like to visit the Eclipse Magnetics US site to view all relevant content for your location?

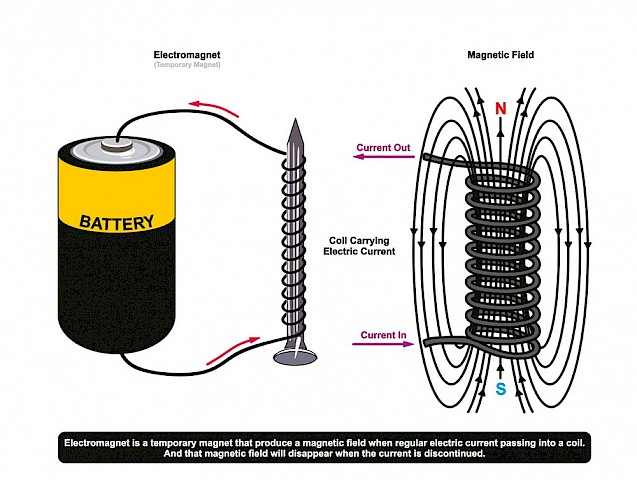

An electromagnet is a magnet powered by electricity and usually has an iron core. Adding an iron core to a solenoid increases its magnetic field strength. The strength of its magnetic output can be easily altered by adjusting the amount of electric current flowing through it, unlike a permanent magnet (where the amount of available magnetic output is fixed). An electromagnet's poles can actually also be flipped by simply reversing the flow of electricity (changing the direction of the electric current).

An electromagnet like this can be simply made by coiling electrically insulated copper wire around an iron nail and passing a d.c. current through the wire. The simplest electromagnet is just a wound coil on free space – called an ironless electromagnet (or ironless solenoid). The magnetic fields from electromagnets follow the same rules as those from permanent magnets - like poles attract and unlike poles repel. Check out our free guide here to discover the difference between Electromagnet & Permanent Magnet.

A solenoid is a type of electromagnet where the coil is usually tightly wound and tends to be longer than its diameter, but it could be any shape. The magnetic field created by electrical currents is very similar to the magnetic field created by bar magnets. In the solenoid, the field is uniform and strong. By adding up the small magnetic fields caused by each coil, the overall magnetic field becomes stronger. In the same way as a bar magnet, the strongest part of an electromagnet can be found towards its two ends.

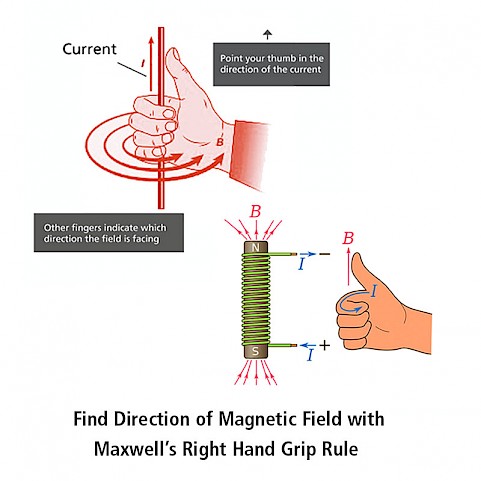

Electromagnets work by generating magnetic fields with electric current passing through an electrical conductor (such as electrically insulated copper or aluminium wire). A single strand or wire, when carrying an electrical current, will produce a magnetic field that goes around the wire, following Maxwell’s Right Hand Grip Rule, where the thumb points in the direction of the current flowing along the wire and the wrapped around fingers show the direction of the magnetic field.

To create a stronger magnetic field, the wire can be wound around to create a coil of many turns (say N turns, wound around a former/bobbin to retain the coil shape). The current passing through these many turns creates a stronger magnetic field within the centre of the coil and we can also use Maxwell’s Right Hand Grip Rule but this time the wrapped around fingers show the direction of the current and the thumb points in the direction of the magnetic field along central axis (the thumb points to where the North pole of the electromagnet is)

If you increase the current, you get more magnetic field. If you increase the number of turns and keep the current the same, you get more magnetic field (increasing the turns increases the coil resistance which would reduce the current for a fixed voltage supply). So you sometimes see the term ampere-turns with electromagnets, which is the number of turns multiplied by the current – more ampere turns means more magnetic output.

Electromagnets can become stronger if we transmit more electric current (I) through their coils and/or wrap more coil turns (N) around the iron core. Both increase the ampere turns which increases the magnetic output, following N x I multiplication rule.

There are four factors that affect its strength:

The number of loops - Whenever loops of a coil are stacked (number of turns, N), the magnetic fields are intensified, creating the effect of a giant bar magnet. Change the number of loops in the coil to increase or decrease the magnetic field strength. More turns, N = more magnetic output. Bear in mind though that increasing the number of turns within a coil will increase the coil resistance which may affect the current within the coil for a given supply voltage.

The metal core - The electromagnet’s central core, if it is a ferrous metal, magnifies the electromagnetic field created. An electromagnet can be made stronger or weaker by changing its metal core material type. Having iron cores makes for very strong fields. The fields are weaker when they have mild steel cores. The strongest fields are made from neodymium magnet cores (need to be careful with the design though). If the core is partially removed from the coil, the field will be weaker since less metal is present inside the coil.

Battery current - When current flows through electromagnets, they produce fields. If you adjust the amount of current flowing through the electromagnet, you will also change the strength of its field. The greater the current, I, in the coil, the stronger the magnetic field will grow.

Wire size - Wires made of metal conduct electricity very efficiently, but they still exhibit some resistance to current flow. When wire of a larger gauge is used on the coil, this resistance will be reduced. By doing this, the current and hence the field will be increased. The strength of the field will also differ if it is made from different types of metal wire, since every metal is different in terms of its resistance to current (e.g. aluminium wire). Changing the wire diameter will also affect how many turns you can put inside some electromagnet designs and this can affect the total coil resistance which then affects the current within the coil for a given supply voltage.

At Eclipse, we specialise in designing & supplying of standard electromagnets (electro-holding magnets / energise to hold electromagnets), electropermanent magnets (energise to release electromagnets) and solenoids for access control, security, safety, machine guards and other claiming applications.

Our team understands the special requirements of product designers, machine designers, electrical engineers, safety managers, and the end user.

Advantages

Disadvantages

Example: A company required a system to clamp mild steel sections and move them around within a confined area, ideally with the ability to clamp and release on a robotic system. We supplied them with energise to release electropermanent magnets that they can control automatically at a distance to their requirements.