Are All Stainless Steels Magnetic?

Stainless steels are not all magnetic. There are magnetic and non-magnetic stainless steels, depending on the composition. To be magnetic, it must meet certain requirements. In order to better understand stainless steel and its magnetic properties, let's examine what stainless steel is.

What is stainless steel?

As an alloy, stainless steel is made up of a combination of metals with the balance being iron but the main alloying element being Chromium. Stainless steel resists tarnishing and rust because of the elements contained within: iron, chromium, silicon, carbon, nitrogen, and manganese. It must be composed of at least 10.5% chromium and at most 1.2% carbon to be recognised as stainless steel.

Chromium (combined with nickel) is the component that gives stainless steel its corrosion resistance. While stainless steel is frequently called stainless, it is not really stainless, because the chromium builds up on its surface making it able to withstand abuse much longer than regular steel without chromium. Passivation is the process of applying chromium to stainless steel to keep the shiny, silver finish.

Picture - The equipment at a dairy plant is made from stainless steel

Types of stainless steel

Stainless steel comes in over 57 types of standard alloy, as well as numerous custom alloys produced by stainless steel manufacturers. The composition of each type varies. Based on their metallurgical properties and microstructures, stainless steels can be divided into five categories:

- Austenitic Stainless Steels

- Ferritic Stainless Steels

- Martensitic Stainless Steels

- Duplex Stainless Steels

- Precipitation-hardened Steels

The Duplex stainless steel combines austenitic and ferritic crystals, so it offers the best of both worlds and is magnetic whilst also having generally greater corrosion resistance than the austenitic 304 and 316 stainless steels.

Ferritic stainless steels - these steels are magnetic primarily due to the presence of ferrite, a compound of iron and other elements. The crystals of ferrite and iron make this type of stainless steel magnetic. It is also important to note that some stainless steels with ferrite have a weak magnetic pull.

Stainless steel grades 409, 430, and 439 are also known as ferritic stainless steels.

Martensitic stainless steels - this category has many types of stainless steel that are magnetic. It is possible for martensitic stainless steel to have a ferromagnetic crystal structure if iron is present. The magnetism of martensitic steel is due to iron being the main component. Martensitic stainless steel has carbon trapped in its crystals are can be hardened to become extremely strong but have reduced chemical resistance compared to austenitic stainless steels.

There are three grades of martensitic stainless steel - 410, 420, and 440.

Austenitic stainless steels - the majority of stainless steels falling into this category are non-magnetic due to high levels of austenite. Despite the fact that some of the alloys, such as grades 304 and 316, contain iron, these materials are non-ferromagnetic. It is the crystal structure that is important for magnetic properties.

By using a thermal process or work hardening (e.g. bending, drilling, etc) austenitic stainless steels can be partially magnetic, forming ferrite in some areas. As a result, austenitic grades exhibit a slight magnetism at mechanically operated edges like sheets.

What makes stainless steel magnetic?

It is necessary that steel contains iron and has either a martensitic or ferritic crystal structure in order to be magnetic.

- There must be iron in the alloy

- The alloy must possess martensitic or ferritic crystal structures

Which types of stainless steel are magnetic?

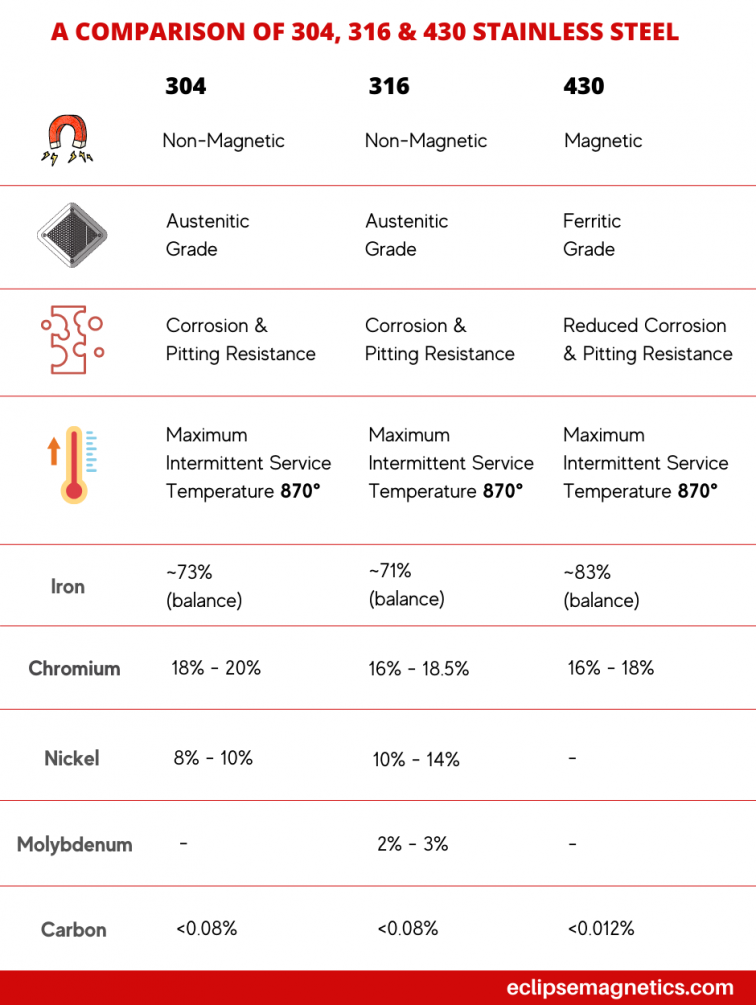

Below are a few examples of magnetic and non-magnetic, given as a quick summary.

- Ferritic stainless steel grade 430 is magnetic

- The austenitic stainless steel grade 304 is not magnetic but it may become a little magnetic in areas that have been cold working (bending, deforming, etc.).

- Austenitic stainless steel grade 316 is not magnetic

This is simplified table compares stainless steel 304, 316 and 430

In stainless steels, why does magnetism matter?

Magnetic fields, when applied to a material, can affect its performance and intended purpose. Magnets can create complications during fabrication and welding processes (a magnetic field can interfere with the weld spark, creating a less tidy weld finish). Electric currents can also behave differently when magnets are used.

Some stainless steels are wanted for their corrosion resistance and are also wanted to either carry a magnetic field (such as 420, 430 grades) but others are wanted for being corrosion resisting and not being magnetic (such as 316). The application requirements will determine which type of stainless steel is better suited.

You may also be interested in topics related to metals and magnetism

Some common grades of Stainless Steel

304 stainless steel - Sometimes also known as SS304 is the most commonly used stainless metal in both industrial and consumer applications. The chromium and nickel alloys in 304 make it resistant to many corrosion attacks. In addition, it is widely used in a wide range of industries since it does not need a post-weld anneal (a reheating and cooling process that relieves metals of heat-induced stress). A 304 stainless steel is made up of 16-24% chromium, as well as alloys such as nickel, carbon, and manganese. Steel 304 has excellent corrosion resistance, so it is suitable for most food applications. However, the presence of chlorides in passivated surfaces can cause pitting.

316 stainless steel (SS316) has the same properties as 304 stainless steel, except with a small addition of molybdenum to increase resistance to chlorides, which makes it more suitable for products such as meat products and mild salted foods. The chemistry of stainless steel 316 is similar to that of 304, but it contains molybdenum as well. Because of this, it resists corrosion much better. As with 304, there is no post-weld annealing required with 316.

316L stainless steel - there is no significant difference between 316L and 316 stainless steel. Carbon content is the only difference between them. Because 316L contains less carbon, it is more corrosion resistant than 316. Post-weld annealing is not required for 316L.

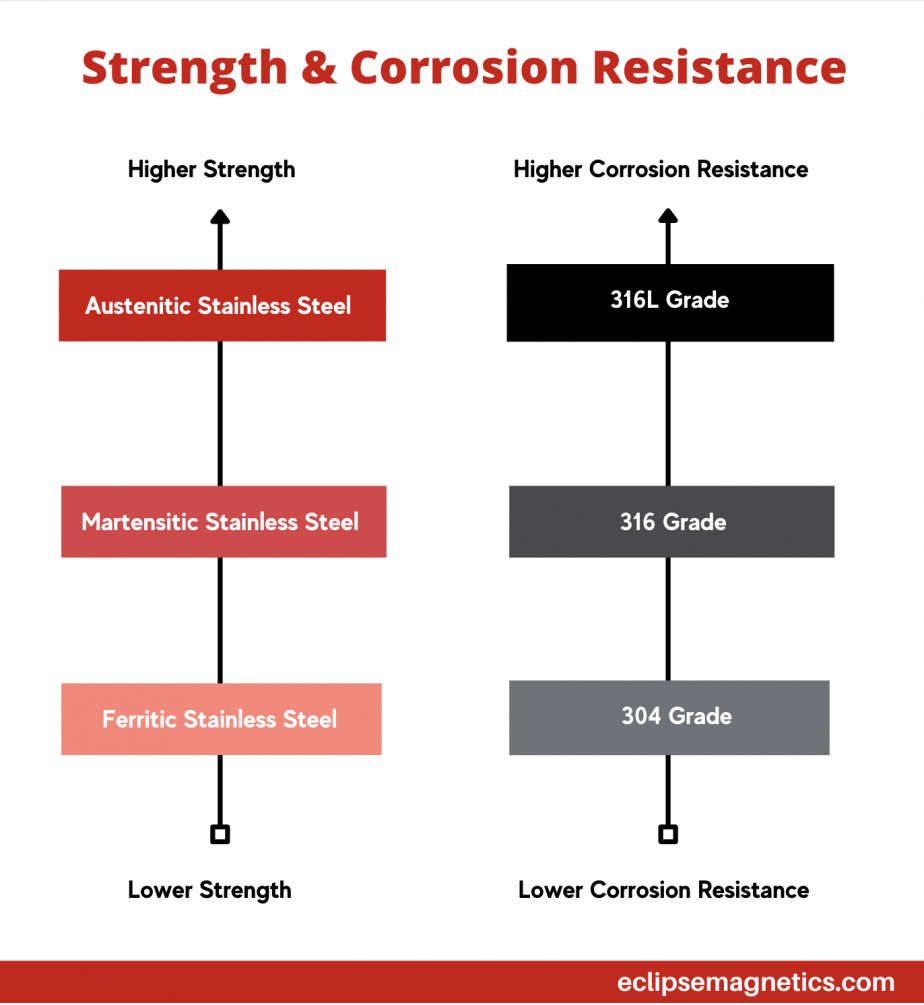

304, 316 and 316L stainless steel are austenitic steels, which refer to their crystalline structure. An austenitic steel is stronger than a martensitic steel or a ferritic steel. The magnetic ferritic steels are low in carbon content, have a low corrosion resistance, and are magnetic.

Based on the diagram below, you can compare the corrosion resistance and strength of different types of stainless steel to give you a quick guide.

Stainless steel with less chromium, molybdenum, and manganese has better corrosion resistance than stainless steel with more chromium and manganese. It is known that stainless steels with magnetic properties, such as 409 and 430, do not resist corrosion as well as stainless steels with non-magnetic properties, such as 304 and 316. It is unrealistic to expect them to. The chromium content in grade 409 is 11%, which is enough though for use in automotive exhaust systems.

In grade 430, 16% of chromium is present, and the material is primarily used indoors. The chromium content of grade 304 is 18%, which makes it ideal for general-purpose uses and outdoor exposure. Grade 316 is needed for marine environments since it has 16% chromium and 2% molybdenum to help it resist salt corrosion.

What's the best stainless steel for the food industry?

When it comes to food processing, stainless steel is available in these three types: 304 (1.4301), 316 (1.4401 or 1.4404), and 430 (1.4016).

Stainless steel 316 (SS316) is very popular in food applications due to its higher corrosion resistance ability compare to 304 grade – where people refer to food grade stainless steel they usually mean 316 stainless steel. The 400-series stainless steels contain more nickel than those from the 300-series, so they are more susceptible to corrosion in harsh environments. Therefore, the 430 is slightly more vulnerable to corrosion in acidic environments, but only if exposure is prolonged. After 430 has been exposed to moisture, it is generally necessary to dry it as soon as possible to prevent corrosion.

The stainless steel material is a popular choice for many sanitary food handling applications. It is not just that stainless steel stands up to temperatures that would melt plastic, but its oxide layer also keeps rust from contaminating food. Food-grade stainless steel contains no chemicals that can migrate into food, which may be the most important factor.

Stainless steel is also beneficial in the food industry for the following reasons:

- Corrosion Resistant: Stainless steel is especially resistant to corrosion compared to other metals, which is why it is ideal for kitchen use. Kitchen equipment is often made from food-grade stainless steel, which can be expensive to install. Because many stainless steel grades are highly corrosion-resistant, it is not necessary to replace the equipment as frequently.

- Strength: Stainless steel is an extremely durable metal, which makes it ideal for heavy-duty items such as equipment and shelves.

- Ease of cleaning: The obvious advantage of stainless steel is that it's easy to clean. Other materials, such as plastic or wood, have grooves or openings where bacteria can enter and grow. It is easy to clean stainless steel because it is smooth and does not provide a place for bacteria to hide. To clean stainless steel properly, always use a food-grade stainless steel cleaner.

- Cost: Stainless steel is a relatively low-maintenance material when properly cared for and maintained.

Using magnets, magnetic separators, and metal detectors in the food industry is critical

It is common for food processing machinery to be made from 304 or 316 stainless steel. At most food processing plants, the product passes through several stainless steel machines and equipment. In the process of thousands of moving parts wearing against each other, small scraps of stainless steel can enter the product flow.

Picture - Production of pralines in a factory for the food industry

As a result, we are frequently asked by customers if magnets can remove fine metal pieces, stainless steel, and even worn-away metal fragments from the equipment. The answer is yes, magnetism can occur in stainless steel with work-hardening, depending on the level of work-hardening, and the grade and size of the stainless steel fragment.

As stainless steel contaminants become mechanically fatigued/work-hardened (a mechanical fatigue process could also be called 'work-hardening') they are now weakly-/ferromagnetic and therefore can be separated using magnetic separation equipment. Also, stainless steel in fine particle form, i.e. when it is under 0.1-3mm in size, changes properties to be paramagnetic. If a magnetic field is applied, it produces a magnetic response in the direction of the field.

Due to the work-hardened stainless steel used in food processing, there is a serious contamination risk. These contaminants can be so small that they are nearly invisible (almost dust-like), therefore it is vital that foreign metal contamination is minimised.

Using both metal detectors and magnetic separators is recommended, as if stainless steel contamination is in a form that outweighs its magnetic susceptibility, then a metal detector is required. But there is also a chance that the metal detector may miss the tiny fragment (less than 3 mm) so high intensity magnetic separation equipment has to be installed upstream. Our stainless steel magnetic separators utilise very high intensity Neodymium (rare earth) permanent magnets, so they will be an excellent solution for the food processing industry.

Explore more related topics to magnetic separation for food processing

A Guide to Magnetic Separation in the Food Industry (Free On-Demand Webinar)

- Why Magnetic Separation and Metal Detection is Vital for HACCP & Supplier Audits

- Guide to Selecting the Right Magnetic Separator

If you’d like to discuss your requirements, Eclipse Magnetics have a team of experts who are able to assess your business needs relating to your food safety and help you select the right equipment for you. If you’d like to book a free consultation, pre-audit site survey or equipment testing, click here.

UK

UK