Finding the Right Magnet Materials: Alnico vs Neodymium NdFeB

With a wide range of magnet materials on the market, it can be difficult to decide which would perform best for your specific application, especially without extensive knowledge of magnetics. As an expert in the field, Eclipse Magnetics offer some of the most effective magnetic solutions throughout a wealth of industries and have vast experience working with high-performance magnets – including rare earth magnets.

With a wide range of magnet materials on the market, it can be difficult to decide which would perform best for your specific application, especially without extensive knowledge of magnetics. As an expert in the field, Eclipse Magnetics offer some of the most effective magnetic solutions throughout a wealth of industries and have vast experience working with high-performance magnets – including rare earth magnets.

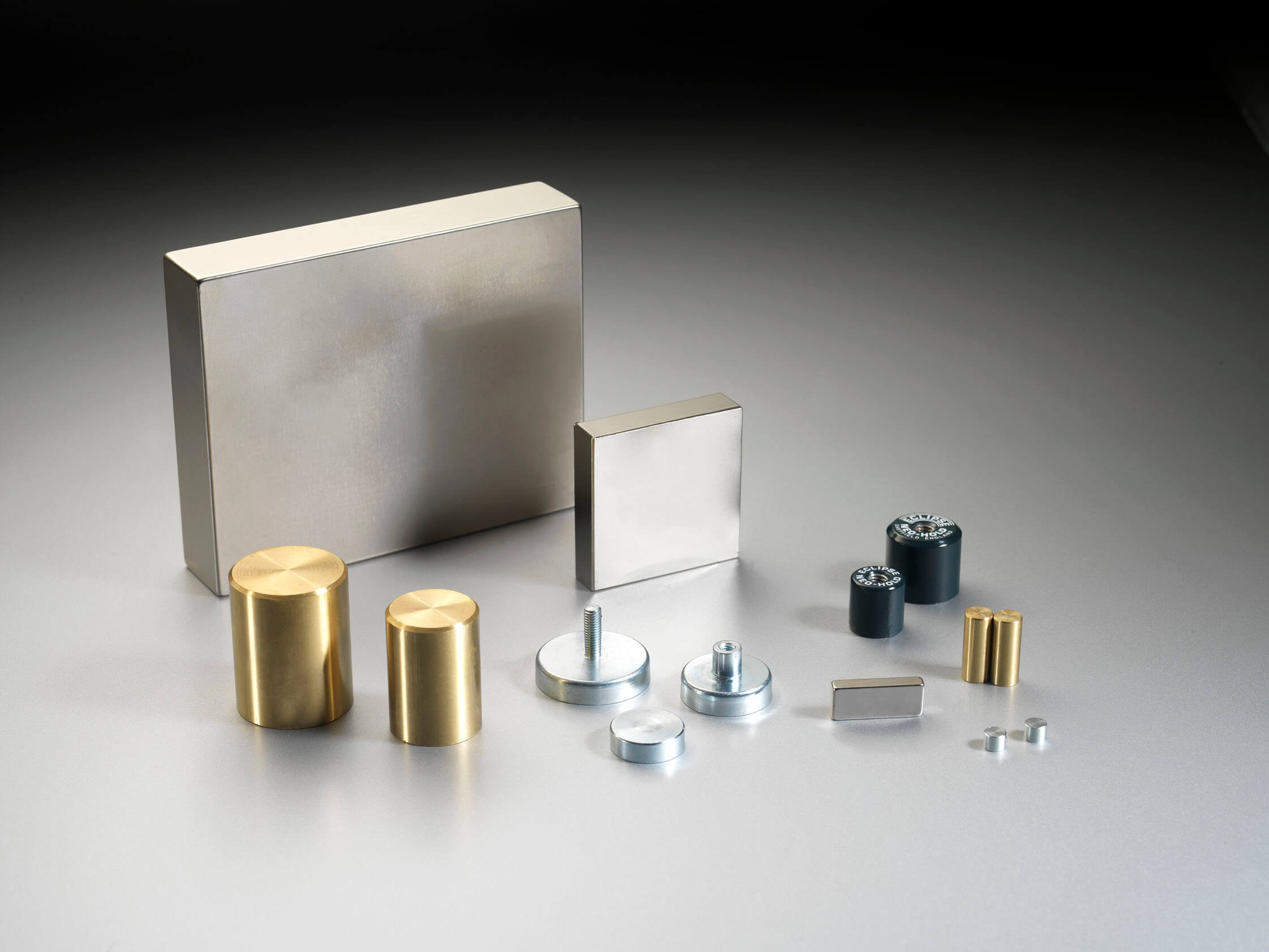

Rare earth or Neodymium magnets are some of the strongest permanent magnets available that boast a significantly higher performance than ferrite and Alnico magnets, yet Alnico remains one of the most popular materials for a vast number of applications. But what are the benefits of these two magnetic stalwarts?

Alnico – A Wonder Magnet

Developed in the 1930’s Alnico was branded a new wonder material, blending aluminium (Al), nickel (Ni) and cobalt (Co) to create a strong-pull magnet (Alnico) that was around nine times that of the tungsten magnet steels and two and a half times that of the best cobalt magnet steels. The composition of the metals within an Alnico magnet resulted in a material that was resistant to high temperature and corrosion.

The iconic red-painted horseshoe-shaped Alnico magnets quickly became the go-to of the magnet world to teach the basics of magnetism. But they also performed extremely well in a whole host of applications including hostile or extreme environments such as oil and gas industry, aerospace, and very high temperature clamping applications.

Eclipse Magnetics was one of the first magnet companies in the UK to start casting Alnico – our expertise and interest in Alnico has always been at the forefront of magnetic technology. We still supply a huge range of Alnico magnets, in varying sizes, shapes and grades across the world.

Alnico magnets are still extremely popular magnetic materials but the material has been known by old names such as Alcomax, Hycomax, Columax, Ax2 and Ax3 but many will probably know it more commonly as Alnico 5, Alnico 8, Alnico 5-7, Alnico 5DG, Alnico 8 and Alnico 9. They are all names for different grades of Alnico magnet material. Modern nomenclature for Alnico now may use LNG or LNGT in the naming, but here at Eclipse Magnetics, we can easily cross-reference the grade of magnet to its modern grade name Alnico equivalent.

Available in isotropic and anisotropic versions, isotropic Alnico magnets can be magnetised in any direction or directions whilst anisotropic can only pull in a pre-determined direction (due to the production methods locking the direction of magnetisation axis within the structure of the magnets). There are varying stages to the production of Alnico magnets – the Alnico magnet production process isn’t just about casting or sintering – there are heat treatment stages as well as tempering including the use of applied magnetic fields; producing Alnico magnets is a technical process and, if done incorrectly, can result in inferior performance to that expected for the grade of Alnico magnet. Most Alnico magnets tend to be anisotropic versions.

Alnico magnets are a great choice for very high temperature applications, with grades capable of operating at temperature up to 550 degrees C (1022 degrees F). Alnico is also well known for having the best temperature stability of magnetic output – as the temperature of the application changes, the magnetic output from a good Alnico magnet is the least of any magnetic material. Alnico magnets are also regarded as having very good to excellent corrosion resistance so can be a great choice for many applications that may be at risk of corrosion (iron, although in the alloy, is usually more corrosion resisting but prolonged exposure to water can start to show corrosion signs longer term). As-cast Alnico magnets can have a blackened outer surface due to being in contact with the sand mold – the outer surfaces can be machined down to give a bright shine metallic finish (always done for the pole faces). However the non-pole surfaces may be coated for cosmetic reasons, hence the historical Red Magnet look – this Red Alnico Magnet appearance is synonymous with Eclipse Magnetics (our history and our experience is long linked to producing and supplying quality Alnico products). Alnico magnets from the 1930’s, 1940’s and 1950’s are known to still exist today and still have their magnetic performance – a testament to the longevity of magnets if properly looked after.

A cost-effective material, with the least variation in magnetic output due to temperature change, an Alnico magnet is ideal for use in very high-temperature applications such as those that use hot oils, clamping, mass spectrometers, as well as precision sensors and meters. If you get the design of an Alnico magnet correct, you can have a high performance magnet that can match or outperform the more ‘modern’ Rare Earth magnets.

There are 29 grades of Alnico including 17 cast grades, 10 sintered grades, and 2 bonded grades. Alnico can be cast in large sizes and more complex shapes (the casting sand mold design and required magnetic pattern may become a limiting factor); sintered Alnico is usually limited to either small or medium sizes and simpler shapes.

Neodymium – The World’s Strongest Magnet

Neodymium (NdFeB or “Neo”) is one of the most common Rare Earth (RE) magnets and offers the strongest permanent magnet available for a given size (the other RE magnet is Samarium Cobalt, SmCo). Created in the 1980’s from an alloy consisting of neodymium (Nd), iron(Fe) , boron (B), and varying amounts of dysprosium and praseodymium, whilst it had held the title of world’s strongest magnet material for many years, its strength can be compromised by high temperatures and corrosion if not coated or protected properly.

Without doubt, NdFeB magnets are one of the most popular magnet types today - Neodymium magnets are used in applications in industries such as medical, science, motors and drives automotive, aerospace and renewable energy sectors. Neodymium magnets, over the past 40 years, have offered a helping hand to many technological and industrial advancements that simply may not have been possible without its existence.

The benefits of Neodymium magnets can far outweigh its disadvantages, mostly due to its strength in relation to size which makes it an ideal option for compact applications or those restricted in space, with a high coercivity (Hci) to resist demagnetisation, giving it vast uses amongst many applications. It also has the ability to withstand extremely cold conditions, being used often with liquid nitrogen applications, which has a boiling point of -196 degrees Celsius (-320 degrees F).

If you want the strongest magnet possible, you always start with looking at NdFeB magnet grades, with N52 and N54 grades being the most powerful grades of Neodymium magnets currently available. Low cost NdFeB grades are rated to +80 degrees C (+176 degrees F) maximum recommended operating temperature. Higher temperature rated grades of Neodymium magnet exist, with the latest versions capable of operating at up to 220/230 to 240/250 degrees C (up to +482 degrees F). But these higher temperature grades of NdFeB cost more for each increment in temperature rating due to containing higher proportions of Dysprosium element (which gives the Neodymium magnets higher Intrinsic Coercivity, Hci /jHc, which gives the NdFeB material the ability to better resist demagnetising from higher temperatures).

Neodymium magnets can have a higher price point than other magnets on the market, but this is due to the price of the raw materials of Neodymium (Nd or PrNd) and Dysprosium (Dy or FeDy) that bump up the production cost.

Which Magnet Material to Choose

When choosing between Alnico and Neodymium magnets, it should always be considered which would work best for the specific application.

Here is a summary of key points when choosing between Alnico and Neodymium:

| Alnico | Neodymium / NdFeB |

Heat Tolerance | Better for higher temperature applications; perfect for improving stability of magnetic output with temperature change | Better for lower temperature applications |

Corrosivity | Very resistant to corrosion | Requires coating to protect from corrosion |

Size | Great for larger sized castings; distance between poles ideally needs to be much longer than the pole face dimensions to get best performance | Better for maximum performance or applications restricted in size |

Cost | Relatively cost efficient | More expensive due to cost of raw materials |

Finding the Right Magnets for Your Application

If you’re looking for more detailed advice about choosing the right magnets for your application, our team can offer their expert knowledge tailored to your specific needs. To book a free consultation, click here, or contact us directly at [email protected].

UK

UK