What to Consider When Using A Magnetic Lifting And Handling System

When using a magnetic lifting system there are important factors to consider which may affect the lifting performance.

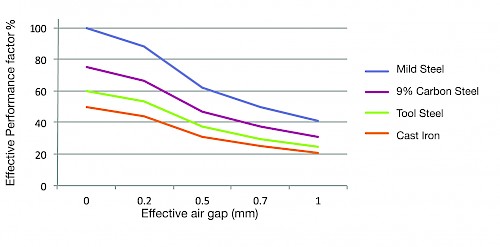

Air Gaps

An air gap between the magnetic surface and the load will reduce holding performance. The highest performance is where air gaps are kept to a minimum and the magnetic hold is maximised.

Air gaps are determined by the profile of the load and the surface finish. For example paint, dust, scale or different surface finishing processes can constitute air gaps.

The chart below shows the effect of different size air gaps on different material types

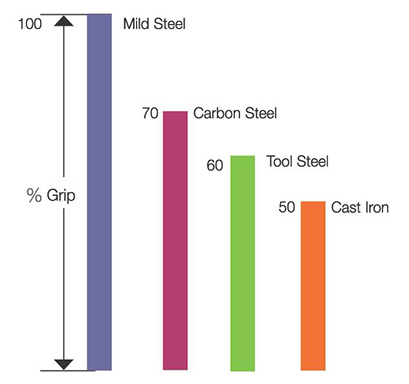

Load Material Type

The material type determines the magnetic hold. Some materials have less magnetic permeability and this will affect the hold. The chart below shows some examples of how the magnetic hold is affected by different material types and the reduction factors to apply.

Stainless steel, brass and aluminium have no magnetic holding capacity so should not be used with these products

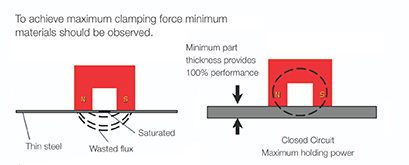

Material Thickness

To achieve maximum holds recommended minimum material thicknesses must be observed. Using with loads outside of the recommended parameters will significantly reduce the hold integrity. Consult the relevant product manual or contact us if you need more details.

Contact Area

Maximum hold will only be achieved when the lifter has full contact area with the load. If the pull face of the lifter poles does not come into contact with the load, for example due to holes in the load surface, the performance will be reduced pro-rata.

To discuss your project please contact us or read more about magnetic lifting and handling.

UK

UK