How do Magnetic Filters Compare to Other Industrial Filtration Methods?

Maintaining clean coolants and lubricating oil is vital in ensuring efficiency and quality output on processes such as CNC grinding, lapping, wash systems, honing, drilling and other “super-finishing” operations.

There are many different types of filter and filtration systems available, and each can make distinct process improvements - but closer inspection may suggest that they are not performing to the optimum levels. You may think your filtration is working effectively, but is it?

Advanced Magnetic Filters

Our advanced magnetic coolant, lubricant and wash system filters or coolant separators have been developed to overcome some of the typical problems experienced when using traditional machine tool filters. They remove almost 100% of ferrous particles, including fine particles. As a result they extend fluid lifespan, save costs on consumable filters, minimise filter waste, and improve product quality. In addition, they offer 24/7 uninterrupted filtration. They are environmentally friendly, reduicing waste disposal of often toxic materials and reducing fluid usage.

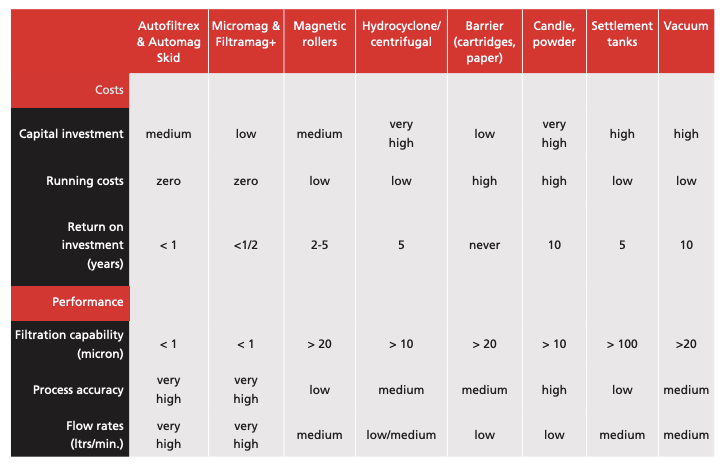

Before choosing a new filtration system or upgrading an existing one, it's important to consider the positives and negatives of each:

Barrier or Media Filters

(e.g. Cartridge filters, sock filters, bag filters, paper bands)

Basic Concept: Fluid passes through some form of barrier usually in the form of a bag, cartridge or sheet made from paper, polyester or polypropylene. The barrier allows the fluid to pass through, but prevents contamination particles from circulating. When full, the barrier is either cleaned, or disposed of and replaced.

Positives +

In applications with low levels of contamination, made up of larger particles, which don’t require an ultra-precise surface finish, barrier or membrane filters provide an adequate and effective means of filtration, and do offer some positives.

- Ease of Control – Differential pressure gives the operator a clear indication when a filter is full and requires changing.

- Capital Cost – Barrier filters are relatively cheap to buy and install. In some cases, the fluid supplier may even subsidise the costs. However, because of the on-going spend on new or replacement consumable filter media, the overall costs are high with a very long return on investment period.

- Non-magnetic Contamination - Barrier filters remove both magnetic and non-magnetic particles, but only to a certain size.

Negatives -

- Replacement Filter Costs – Barrier filters are usually disposable items, and when they become blocked or blinded they are replaced. In medium to heavy contamination applications, the costs of replacement barrier filters can be enormous. In addition, there are downtime costs each time the machine is stopped to replace the filters.

- Environmental Costs – Using disposable filters not only results in significant disposal costs, but also environmental damage because used media is sent to landfill sites. With the advent of ISO14001 and more corporate focus on environmental responsibility, many companies are looking to reduce waste and ISO14001 often features in tender submissions. Cartridges, bags, socks and band filters are often contaminated with fluids and ferrous mud which mean they require expensive specialist disposal. The lifespan of oils, coolants, cutting fluids and lubricants is often reduced, as theri limited filtration capability (see below) means that fluids are not fully cleaned and need more regular change. Barrier filters with a small pore size can strip away natural additives such as anti-bacterial properties and anti-foaming properties which also reduces the lifespan of the fluid.

- Limited Filtration Capability – In order to maintain flow, barrier filters are often limited by the media pore size. To avoid restricting flow, the pore size may be typically set at 10-20 microns, which means that any contamination particles below this size continue to be circulated. As a result, components may be damaged, surface finish quality reduced, process accuracy may be reduced, and oil/coolant lifespan also reduced.

- Downtime – In medium to high contamination applications, barrier filters are susceptible to blinding or blocking, which causes a drop in pressure which in turns triggers the machine to stop. In certain applications this can result in hours of downtime and maintenance time.

Settlement Tanks

Basic Concept: During the machining cycle, fluids such as coolants,oils, cutting lubricants are often pumped into a holding or settlement tank where larger ferrous particles fall to the bottom of the tank through natural gravity settlement. In some cases they are removed by a drag conveyor, but in most cases contamination particles accumulate to point where the tank has to be drained and manually cleaned in a "digging out" operation.

Positives +

- Filter Media Costs -The main advantage of settlement is that there is no on-going investment in disposable or cosumable barrier or membrane filters. Natural gravity does the work.

- Primary Separation - Settlement provides adequate, cost effective means of primary separation of larger particles, typically 100 microns or larger. This does reduce the burden on secondary filters.

Negatives -

- Ineffective Filtration Capability - Settlement relies on the weight of the particle and the time the fluid remains in the tank in order to be effective. If the particles are small, low density, or pass through the tank quickly, natural settlement is largely ineffective as a means of industrial filtration. Generally, any contamination particles below 100 micron size continue to circulate; damaging finished product, damaging process equipment, and reducing the quality/lifespan of the fluid.

- Downtime - Manually cleaning the holding tank can be an expensive process in terms of direct man hours and resultant process stoppages. The "digging out" out process can mean the process is out of action for 24-48 hours.

- Reduced Fluid Quality - The lifespan of coolants and oils can be significantly reduced as contamination is recirculated and gradually builds up in the fluid. Dirty fluids require more regular change

- Secondary Filtration Required - For effective filtration to be achieved, an additional secondary filtration method will usually be needed to work in conjunction with the tank. A settlement tank is rarely the sole solution for the as a filtration or coolant separation system.

- Waste Disposal - the "digging out" or tank flushing process results in a "mud" like accumulation which often needs expensive specialist disposal. This black sludge like material can be classed as hazardous or contain bacterial build up.

Cyclonic Separation

Basic Concept: Cyclonic, centrifuge or hydro-cyclonic filters or separators are widely used. The general principle relies on the different densities of the liquid and contamination particles to accelerate natural settlement. Fluid flows in a cyclonic pattern around a vessel wall, and centrifugal force separates out contaminated particles which are forced downwards for collection, whilst clean fluid flows out and back to the machine.

Positives +

- Filter Media Costs - After an initial capital investment on the centrifugal separator or filter, there are no on-going consumable filter media costs or disposal costs.

Negatives -

- Filtration Capability - Generally, cyclonic systems can only extract medium to larger contamination, with low density or smaller particles still passing through. In many cases, anything smaller than 10 microns will continue to circulate causing on-going damage to finished parts and process equipment, as well as reducing fluid quality.

- High Maintenance - Many cyclonic systems need regular cleaning to remove contamination and prevent outlets from becoming blocked. Resulting in machine stoppages.

- High Capital Investment Costs - On larger machine tool applications, cyclonic or centrifuge filtration systems can represent a high capital investment cost when compared to other filter systems.

- Flow Restrictions - Due to the nature of the process, cyclonic systems are often unable to handle higher flow rate applications required by large volume machining processes or multi-cell machines

- Waste Disposal - the waste produced by centrifuge separators or filters is cannot be recycled it often comes in a sludge form which needs to be disposed of

Traditional Magnetic Systems

When magnetic filters or magnetic separation is mentioned, many people think of traditional methods such as a ferrite magnetic rod or bar magnet mounted or suspended in a holding tank, or a low intensity magnetic roller such as a coolant roller. This is by far removed from the advanced magnetic filtration systems now available.

Basic Concept: Traditional magnetic filters rely on a magnetic field to attract ferrous particles as the device comes into contact with the fluid, thereby removing it from circulation.

Postives +

- Filter Media Costs - Magnetic filtration or separation relies on a permanent magnetic field and therefore does not need any consumable items and has no on-going running costs.

- Primary Filtration - In applications which don't require a precision finish, contamination particles are large and the flow rates low, traditional magnetic filters or separators can be a cheap and effective solution.

Negatives -

- Limited Filtration Capability - Traditional magnetic systems can be used as primary filters to remove large particles. But if they are used as the sole means of filtration, they are ineffective in precision finishing applications. They are often limited by magnetic strength as low intensity magnets are often used. They are also limited by design; in most cases the fluid does not flow close enough or for long enough around the magnet to be effective. Large, rapidly moving volumes of contamination continue to circulate resulting in the negative effects previously discussed.

- Downtime - Traditional magnetic coolant filters or separators are often badly designed and not user friendly when being serviced. This can result in long periods of downtime and a laborious, dirty cleaning operation.

- Secondary Filtration - to be effective traditional bar magnets or coolant rollers also need some means of secondary filtration which results in extra investment costs

Vacuum Filters

Basic Concept: Vacuum filters use vacuum or suction to draw fluid through a filter media. Clean fluid flows into a “clean” tank, and contamination is held on the filter media which is periodically cleaned.

Positives +

- Automation - Such systems are often automated, which reduces downtime or manual intervention for cleaning.

- Higher Flow Rates – Vacuum filters are available for larger applications which handle high volumes of fluid and higher flow rates.

Negatives -

- High Capital Investment - Many vacuum filtration systems are hugely expensive investments. Whilst they are effective for some applications, the return on investment is over a very long period.

- Filter Media Costs - Vacuum filters rely on a filter media to capture the particles. In some cases this media can be cleaned and reused, however it will ultimately need replacing, resulting in costs and disposal issues.

- Filtration Capability – Whilst vacuum filtration systems generally have an improved capability than standard barrier filters, they are not fully effective for high precision processes. The market leading vacuum filters can remove particles down to 1 micron size, but many other systems only operate at 5-10 microns. The problem with this is that smaller sub-micron particles remain in the process; damaging process equipment, reducing part quality, and reducing the fluid life.

See the comparison summary table below:

Note: This is general information for guidance purposes only. Please consult Eclipse Magnetics for application specific information.

UK

UK