What Is A Pot Magnet? Pot Magnets Explained

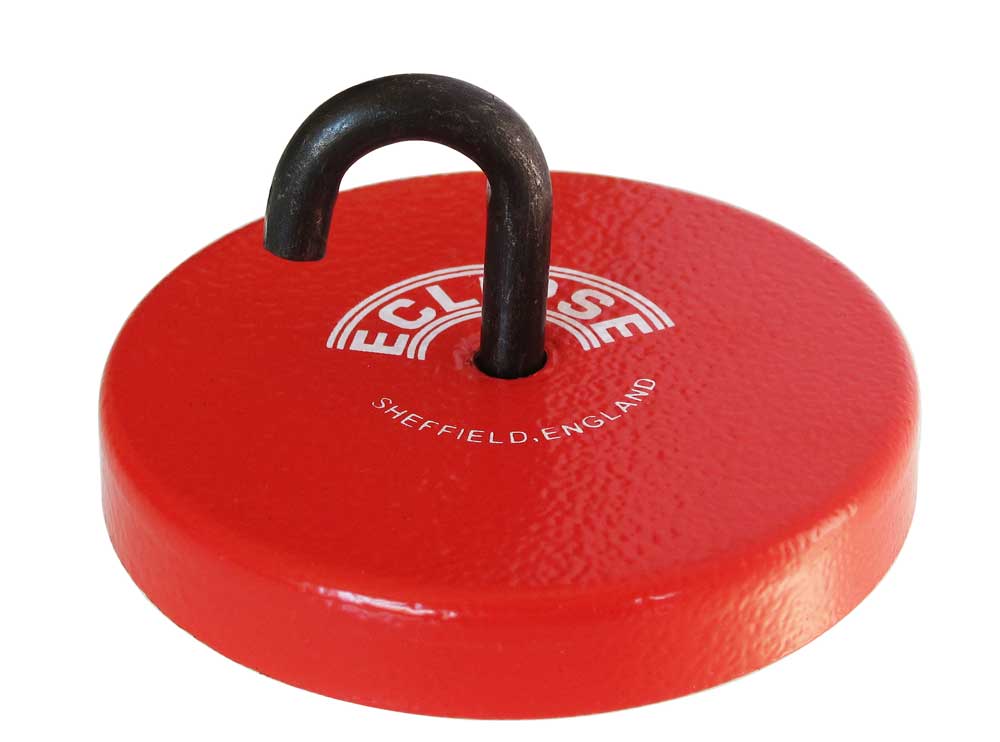

"What is a pot magnet" is a question that we are commonly asked. The answer is relatively simple. A pot magnet is a magnet that is contained within a casing or housing. It can be a simple cylindrical magnet, or it can have accessories such as hooks or threads for use in other applications.

In this article, we'll tell you everything you need to know about pot magnets, including where they're used and the different types available.

Ideal for Routine Clamping Applications

A typical Pot Magnet usually consists of a magnet contained within a casing or housing. The ferromagnetic housing is often a plated mild steel material but ferritic stainless steel (400 series) is also used, which is popular for its corrosion resistance. See our range of pot magnets.

The pot magnet typically clamps with high concentrated magnetic forces when in direct contact with ferrous based surfaces. The clamping / pull force, when in direct contact, is normally higher than conventional standard magnets. This is because the magnetic circuit is optimised for clamping applications (by removing air gaps from the magnetic circuit).

Typical Pot Magnet Construction

A typical pot magnet has only one surface which exerts a magnetic field, thereby creating a concentrated clamping force. The magnetic face is exposed from the casing. You will probably find a typical pot magnet is supplied with a keeper plate which covers the magnet face whilst in transit or being handled.

When designing pot magnets, we design them to provide maximum pull force relative to the size of the magnet – to do this we design out air gaps from the magnetic circuit of the assembly. The ferromagnetic casing directs the magnetic field directly to the surface to be clamped to make a highly efficient. So, if a magnet has its North face visible, the ferrous ring of mild steel around the outside of the magnet is acting like a South pole – in effect giving two poles on the clamping surface making a short distance between poles for magnetism to travel through the clamped surface.

Typical Pot Magnet Fixings & Attachments

Pot magnets allow a wide array of means of fixing them onto customer’s components due to variations in the ferromagnetic cup housing design. Pot magnets can include threaded bars (male threads), tapped threaded holes in the housing material (female threaded hole / boss / screwed bush / internal thread), countersunk holes for screws, counterbore holes for bolts and even blind ended for simply gluing into place – some versions are even precision ground on the outer diameter to allow an interference fit. Pot magnets have the advantage over conventional magnets, with conventional magnets you cannot put threads onto magnets themselves because they are too brittle so cannot take the forces that threading requires.

Extra Protection

Pot magnets also protect the magnets inside them, which really aids in high clamping force pot magnet applications. The steel housings ensures that the pot magnet is much more durable, being protected from impact damage or load bearing damage. The cup or casing shields the magnet – ideally the pot magnet is produced such that is is ever so slightly inset relative to the face of the ring of the cup so any mechanical hits should be on the steel rather than the magnet limiting the breakage risk. Press fitting of pot magnets in place is feasible when using pot magnets (not possible with magnets on their own) – the cup protects the magnet and takes the compressive forces instead; specially produced pot magnets are required (which we offer). The protective casing improves resistance to corrosion by reducing exposure to corrosive conditions.

Pot Magnet Clamping Forces

Pot magnets are always rated by a clamping force (which is the maximum possible pull force the pot magnet can achieve). They are designed for clamping so they are rated in kg pull or N pull (1kg pull force is ~9.81N pull force). Although they contain magnets rating them by a magnetic field strength is never advised – you will measure large variations across the clamping face going from a North pole in the centre to a South pole surrounding it).

Pot magnet pull forces are tested on high quality thick mild steel test parts. If the material being clamped onto is thin, the maximum pull force you will achieve may become less than the rated pull force – as the material gets thinner, the measured pull force reduces further. If this happens and you need more pull force, you either need to increase the thickness of the material you are clamping onto, use more pot magnets to multiply the force, or you could use more smaller pot magnets with a shallower magnetic field.

If the material being clamped onto is of poor ferromagnetic quality (rusty, low magnetic permeability, curved, coated/painted, thin, meshed, etc) the ability of the magnetism to interact with the material to produce the high pull force becomes limited.

Pot magnets resist sliding better than many other magnets. As a general guideline rule, where a standard magnet takes one fifth (20%) of its direct pull force to start to slide over a surface (shear force), a pot magnet typically takes one third (33%) of its direct pull force to start to slide over a surface (shear force). And rubber / polyurethane coated pot magnets have even higher friction so have even higher shear forces (often having the ability to have a shear force exceeding the direct pull force). The rubber coated pot magnets not only offer superior slide resistance, they also help protect painted/coated surfaces from getting scratches.

Pot magnets do not work well when trying to clamp though larger air gaps. For the best pot magnet performance the pot magnets should be in direct contact with the mild steel they are to clamp onto (simply due to how pot magnets are designed). Likewise pot magnets are not really designed for pot magnet to pot magnet clamping – it is possible but we would have to produce North and South versions to get the required attraction .

Pot Magnet Materials

Ferrite, Alnico, Neodymium NdFeB and Samarium Cobalt SmCo materials are all commonly used within pot magnets. Each type has its own properties and characteristics. Size for size, the NdFeB versions will be the most powerful and the ferrite versions will be cheaper but least powerful (size for size). SmCo versions will be not far behind NdFeB for performance but will have better temperature characteristics. Alnico versions will have a range of performances depending on their design but will be better for higher temperature applications. Read more about magnet materials

Temperature Resistance

A typical pot magnet can supply pull forces varying from less than 1kg to up to 130kg (higher is possible). Most pot magnets can work up to +80 degrees C (rubber coated version up to 60 degrees C). At higher temperatures either the magnet material becomes a limitation (standard NdFeB material limited to +80 deg C, but higher temperature grades can be used) or the production method may become the limitation (e.g. adhesive temperature limitation, or expansion coefficients causing problems). So some Alnico pot magnets may be rated at 220 deg C (even though alnico may be fine up to 450-550 deg C) because the materials of the pot magnet design expand at different rates causing the assembly to risk becoming loose above that temperature. But to solve this we produce special pot magnets that can operate at up 450-550 degrees C (for use in high temperature applications such as welding for example). We provide magnetic solutions for various applications and can take into account the environmental conditions.

A Range of Options

The pot magnets then come with varying styles to suit nearly every application:-

With hooks or eyebolts, countersunk (for screws), through hole (for bolts and cap head screws), male and female threaded (for attachment to nuts or into threads), blind ended (for press-fitting), etc.

They may have variants to their names which usually describe how they work or their shape/style e.g. limpet pots which use a threaded hook to assist prising the magnet off from the clamped surface, shallow pots which are hot very thick, deep pots which are tall, bi-pole pots (a variant with a North and South half-moon mild steel poles and no magnet visible).

At Eclipse Magnetics, we stock a vast array of pot magnet designs – chances are that we already have an off-the-shelf solution to your requirements. But, because we produce and supply custom magnetic assemblies, we can supply pot magnets to a variety of sizes and performance criteria with the ability to add fixing means to meet the customer requirements. We make pot magnets to order.

See our range of Pot Magnets

UK

UK